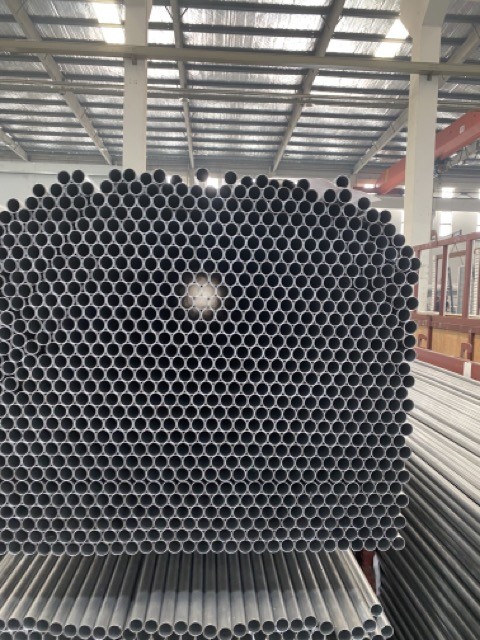

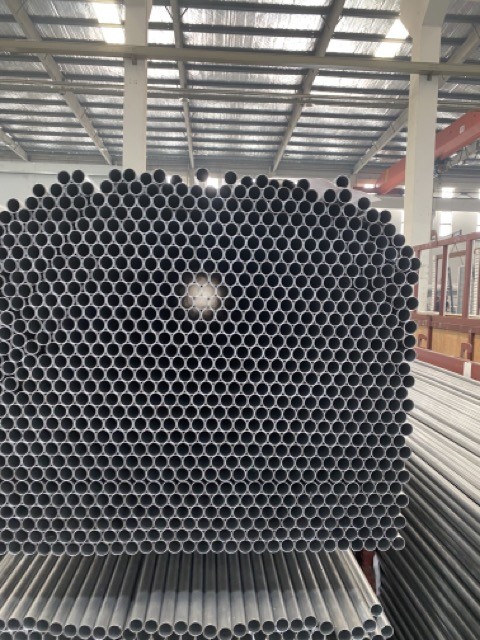

3003 H14 Anticorrosive Aluminum Alloy 3 Series Outer Diameter Φ 22

mm

Product Description:

The aluminum alloy tube used in heat exchanger mainly produces 3

series aluminum alloy, 1 series aluminum alloy, 6 series aluminum

alloy, 5 series aluminum alloy.

This product is mainly used for various cooling heat exchange

tubes. Widely used in air conditioning, refrigerators, heating and

air conditioning equipment.The series of aluminum alloys have good

corrosion resistance and weldability.

Aluminum alloy is one of the most widely used Non-ferrous metal

structural materials in industry. It has been widely used in

aviation, aerospace, automobile, machinery manufacturing, ship

aluminum alloy and chemical industry.

Our company is a high-performance high-reliable professional heat

exchanger aluminum tube manufacturers, is specialized in the

production of various specifications of aluminum coil and aluminum

straight tube, suitable for a variety of refrigeration, heat

exchange equipment and other supporting equipment industry.

Features:

3003 is an AL-Mn alloy, which is one of the most widely used

anti-rust aluminum. The strength of this alloy is not high

(slightly higher than that of industrial pure aluminum) , and it

can not be strengthened by heat treatment, therefore, the cold

working method is adopted to improve its mechanical properties:

high plasticity in the annealed state, good plasticity in the

semi-cold work hardening, low plasticity in the cold work

hardening, good corrosion resistance and good weldability, poor

machinability. Applications are mainly for low-load parts requiring

high plasticity and good weldability, working in liquid or gaseous

media, such as fuel tanks, gasoline or lubricating oil conduits,

various liquid containers and other low-load parts made by deep

drawing: wire used for rivet 3003 aluminum plate formability,

solubility, corrosion resistance are good. For machining parts

requiring good formability, high corrosion resistance, good

weldability, or requiring both these properties and work that is

stronger than a 1XXX series alloy, such as kitchenware, food and

chemical product handling and storage devices, tanks and tanks for

transporting liquid products, various pressure vessels and

pipelines processed by sheet metal, heat sink, cosmetic board,

Photocopier Rollers and marine materials.

The company always adhere to scientific and technological

innovation, deep cultivation of industrial cutting-edge technology,

and strive to industry customers and partners continue to enable,

win-win.

Techical Parameters:

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

The specifications in the form can be customized according to

customer's requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat

treatment-flaw detection -forming-inspection-finished product

packaging

Stright pipe

Raw material

procurement-inspection-cleaning-extrusion-coiling-straightening-flaw

detection-fine cutting-cleaning-heat treatment-inspection-finished

product packaging

Support and Services:

We support and provide technical services for the use of aluminum

pipes and assist customers to solve the production problems arising

during the actual use process. Including the performance detection

of aluminum pipe, technical analysis, the use of the back channel,

aluminum pipe welding, aluminum pipe pipe, aluminum pipe bending,

finished product leakage detection, etc., at the same time in the

use of related problems, we will also assist customers to solve

problems in the first time. And make corresponding adjustments

according to the actual situation.

FAQ.:

Q1: What kind of material alloy is the product?

A1: Currently, there are 1 series, 3 series, and 6 series aluminum

alloy.

Q2: What state and performance of the aluminum pipe can be

produced?

A2: can produce from hard state to soft state and interval

performance products

Q3: Can I customize the product specifications and requirements?

A3: Different specifications and states can be customized according

to the requirements, such as fixed ruler straight pipe and coil

pipe

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.