Precise 3003H14 Aluminum Tube Pancake Coil for Automotive &

Aerospace Applications

Aluminum tube pancake coil 3003H14 is a unique and excellent

aluminum product, carefully cast from 3003 aluminum alloy, which

has been widely praised for its outstanding plasticity, corrosion

resistance and welding performance. The H14 logo symbolizes that

this product has been precision hardened during the manufacturing

process. This optimization gives it higher strength and stability.

Its precise specifications, the outer diameter can be customized,

and the wall thickness can also be customized including length

customization, ensuring that it exhibits excellent performance in

various applications requiring high precision.

3003 aluminum alloy is an aluminum alloy material with high

strength, good corrosion resistance and excellent plasticity. Its

properties have been widely used in automobiles, aerospace,

electronic products and other fields. H14 hardening treatment is a

treatment method that can significantly improve the strength and

stability of metal materials, and can also enhance wear resistance,

fatigue resistance, corrosion resistance and other properties.

Therefore, this H14-hardened 3003 aluminum alloy material exhibits

excellent performance.

In general, the aluminum tube pancake coil 3003H14 is a

high-quality and unique aluminum round tube. It is carefully cast

from high-quality 3003 aluminum alloy and undergoes precision

hardening treatment to meet the high-precision requirements of

different application scenarios. As a well-received aluminum round

tube, it can demonstrate excellent performance and long-term

durability no matter what field it is used in.

Features:

Our aluminum tube pancake coil 3003H14 is a carefully designed and

manufactured product that not only has excellent physical and

chemical properties, but also has a variety of application

scenarios. Through strict production processes and quality control

systems, we ensure that every product meets the highest quality

standards. Choose our aluminum tube pancake coil 3003H14, you will

enjoy the following unparalleled advantages:

1. High quality: We always pay attention to details and ensure that

every aspect from material selection to production and

manufacturing meets the highest standards. Through advanced

technology and equipment, we precisely control alloy composition,

product size and mechanical properties to ensure that every product

meets or exceeds customer expectations.

2. Durable: The characteristics of aluminum tube pancake coil

3003H14 make our aluminum tube pancake coil have excellent

corrosion resistance and wear resistance, and can withstand the

test of various harsh environments. Whether in the highly corrosive

chemical industry or in the mechanical manufacturing field with

severe wear and tear, our aluminum tube pancake coil strips can

maintain long-term and stable use.

3. Precise size: We use advanced processing equipment and precise

control methods to ensure that the size of each aluminum tube

pancake coil is accurate within the specified range. Whether it's

large vessels, complex heat exchangers, or high-precision chemical

processing equipment, we can meet their stringent requirements for

dimensional accuracy and stability.

4. Wide application: Thanks to its excellent physical, chemical and

welding properties, our aluminum tube pancake coil 3003H14 has wide

applications in many industrial fields. Whether it is used to

manufacture various types of containers, heat exchangers, chemical

processing equipment, etc., or is used to manufacture various

welded components, it can exert its best performance. No matter

which industry you are in, you can find an application for the

aluminum tube pancake coil 3003H14, which is a truly versatile

aluminum round tube that can meet a variety of needs.

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat

treatment-flaw detection -forming-inspection-finished product

packaging

Stright pipe

Raw material

procurement-inspection-cleaning-extrusion-coiling-straightening-flaw

detection-fine cutting-cleaning-heat treatment-inspection-finished

product packaging

echical Parameters:

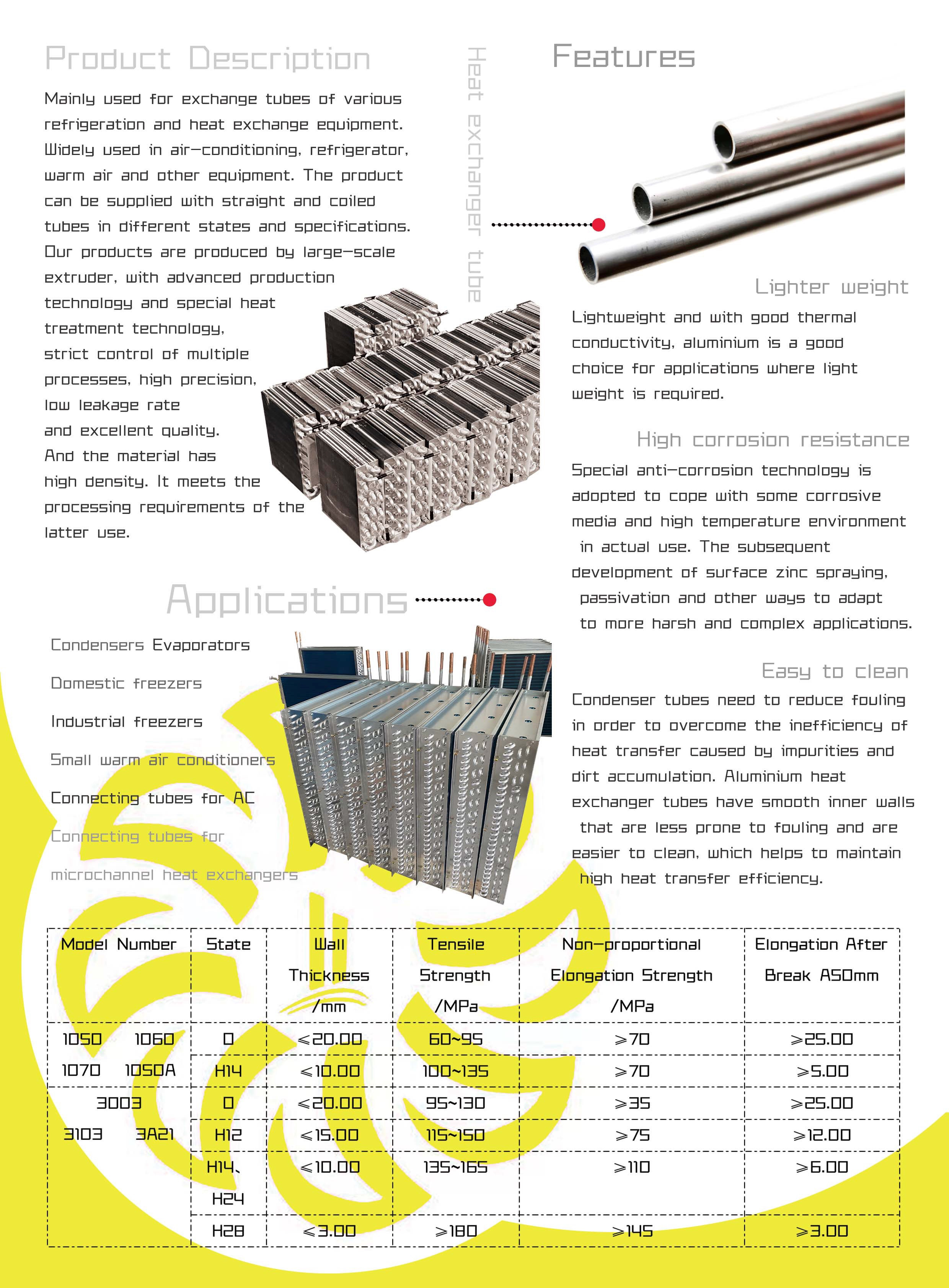

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

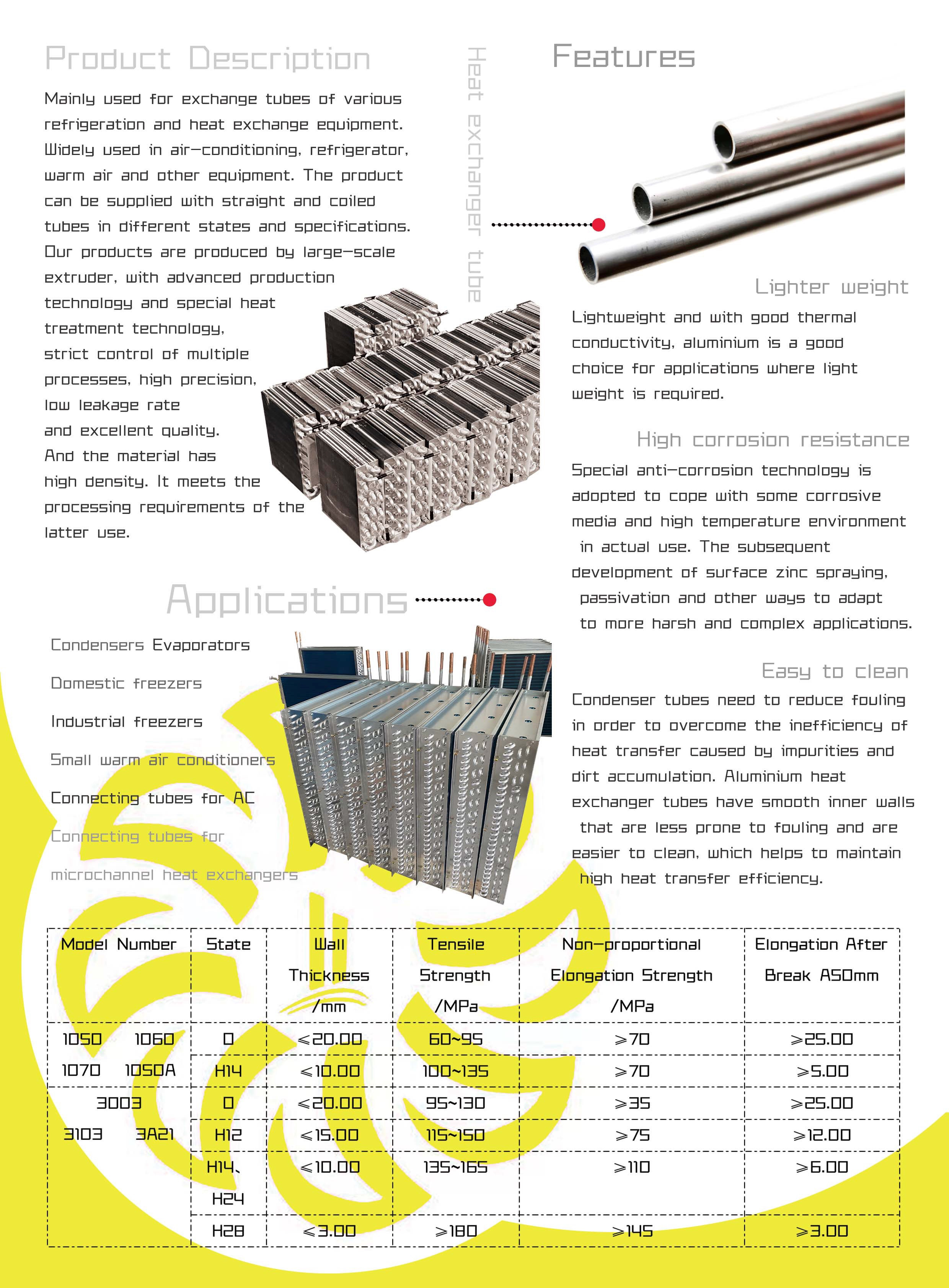

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

Specifications can be customized according to customer

requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

HOW TO ORDER

Firstly,here is a more detailed product description about Aluminum

Alloy Tubes of Heat Exchanger.

Heat

Exchanger Tube-1.pdf

Hear

Exchanger Tube-2.pdf

You can then download a form from this website and fill it out with

basic details.

Send it to the provided e-mail address, and our engineers will

price you based on the technical specifications.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

Alternatively, you can download the Technical Data Requirements

Sheet directly.

Yuneng Product Requirements Table.docx