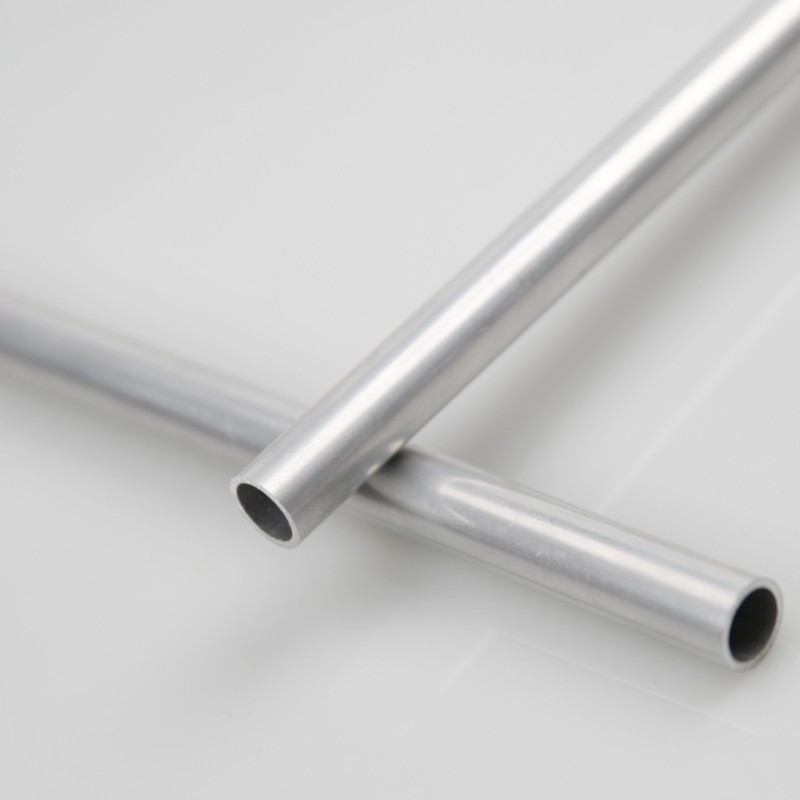

High performance 3003H14 aluminum wire rod for complex products

3003H14 aluminum wire rod is a high-quality aluminum round tube

carefully crafted from 3003 aluminum alloy, which is highly praised

for its excellent plasticity, corrosion resistance and excellent

welding performance. H14 means that this product has undergone

rigorous hardening treatment to ensure its strength and stability,

providing a solid guarantee for subsequent applications.

The outer diameter of this aluminum wire rod is accurate to

15.39mm, and the wall thickness is controlled at 0.8mm. This

high-precision dimensional control allows it to demonstrate

excellent performance in various application scenarios that require

extremely high precision. This is not only reflected in its

exquisite appearance, but also in its rigorous craftsmanship and

excellent performance. Whether in precision machinery, automation

equipment or other fields that require high-precision aluminum

products, 3003H14 aluminum wire rod has won widespread praise for

its excellent performance and stability.

Not only that, due to its excellent plasticity and corrosion

resistance, it can easily cope with the processing of many complex

aluminum products, showing extremely high applicability. 3003H14

aluminum wire rod maintains good plasticity, making the aluminum

products produced with higher precision and better performance.

To sum up, 3003H14 aluminum wire rod has excellent plasticity,

corrosion resistance and excellent welding performance, as well as

excellent strength and stability obtained after hardening

treatment, coupled with high-precision dimensional control, making

it an ideal choice for aluminum wire rods. It is unique among round

tubes, especially in applications requiring precision manufacturing

and high performance.

Features:

Our 3003H14 aluminum wire rod is a carefully designed and

manufactured product that not only has excellent physical and

chemical properties, but also has extremely high durability and

reliability. During the manufacturing process, we employ strict

quality control measures to ensure that every product meets the

highest quality standards. Therefore, customers who choose our

3003H14 aluminum wire rod can enjoy the following advantages:

First of all, our aluminum wire rods have excellent corrosion

resistance and wear resistance, and can maintain their original

performance and precision for a long time. This is due to the

3003H14 aluminum alloy material we selected, which has excellent

performance in corrosion resistance, high temperature resistance

and oxidation resistance, and can maintain stable performance in

various harsh environments.

Secondly, our aluminum wire rods have extremely high plasticity and

processability and can be easily processed into aluminum round

tubes of various shapes and sizes. This makes our aluminum wire

rods widely used in various industrial applications, whether it is

manufacturing various types of containers, heat exchangers, or

chemical processing equipment, etc., we can meet your needs.

Finally, our aluminum wire rods also have excellent welding

performance and can be easily welded with other metal materials and

are suitable for manufacturing various welded components. This

means you can choose our 3003H14 aluminum wire rod to meet your

specific industrial application needs and be easily connected and

assembled with other metal materials.

In summary, our 3003H14 aluminum wire rod is a high-quality,

durable and easy-to-process product with a wide range of

applications and excellent welding performance. No matter which

industry you are in, you can choose our 3003H14 aluminum wire rod

to meet your needs and enjoy our high-quality service and technical

support.

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat

treatment-flaw detection -forming-inspection-finished product

packaging

Stright pipe

Raw material

procurement-inspection-cleaning-extrusion-coiling-straightening-flaw

detection-fine cutting-cleaning-heat treatment-inspection-finished

product packaging

echical Parameters:

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

Specifications can be customized according to customer

requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

FAQ.:

Q1: What kind of material alloy is the product?

A1: Currently, there are 1 series, 3 series, and 6 series aluminum

alloy.

Q2: What state and performance of the aluminum pipe can be

produced?

A2: can produce from hard state to soft state and interval

performance products

Q3: Can I customize the product specifications and requirements?

A3: Different specifications and states can be customized according

to the requirements, such as fixed ruler straight pipe and coil

pipe

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.